BMS-16i

Answering tough demands

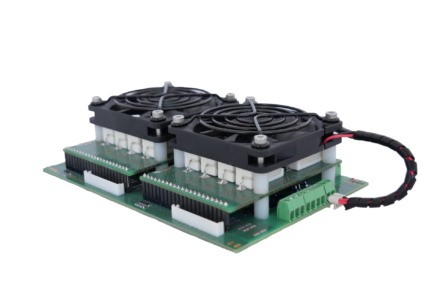

Depending on mechanical design of the battery pack, this bms-16i might be beneficial using the solution with concept of multiple BMS modules, which are not located directly at each “S” (serial) cell, but inside the battery pack (or inside the charger for balancing charger variant) and concentrically dissipating the waste heat. Depending on the required balancing currents (charging / balancing time), these types are produced in variants of 100mA and 850mA.

BMS-16i type provide balancing during the charge as well as the “permanent” balancing methods.

As a standard, MGM COMPRO intelligent battery management systems feature modularity to care for almost unlimited number of cells, unique connectivity and diagnostics, safety and reliability, various communication protocols (automotive and aerospace) including the possibility of customisation. Weight of BMS 16i – 82 g, Weight of BMS 16i with HCBAL8s and FANs – 305 g.

Would you like to see a datasheet for this product?

Please enter your email address and phone number, we will get back to you with the datasheet shortly.

New horizons of safety

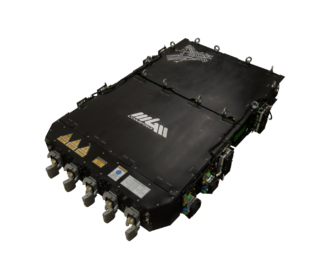

The essential feature is unrivaled reliability thanks to having all the crucial components doubled. Moreover, these types provide you with the most advanced hardware real-time self-checking, which makes MGM COMPRO Battery Management systems one of the most reliable on the market.

Born to be Airborne

Both MGM COMPRO’s battery management systems BMS8i and 16i fit perfectly for aircraft applications. Besides many other key features, MGM COMPRO also offers the option of airborne logic of use.